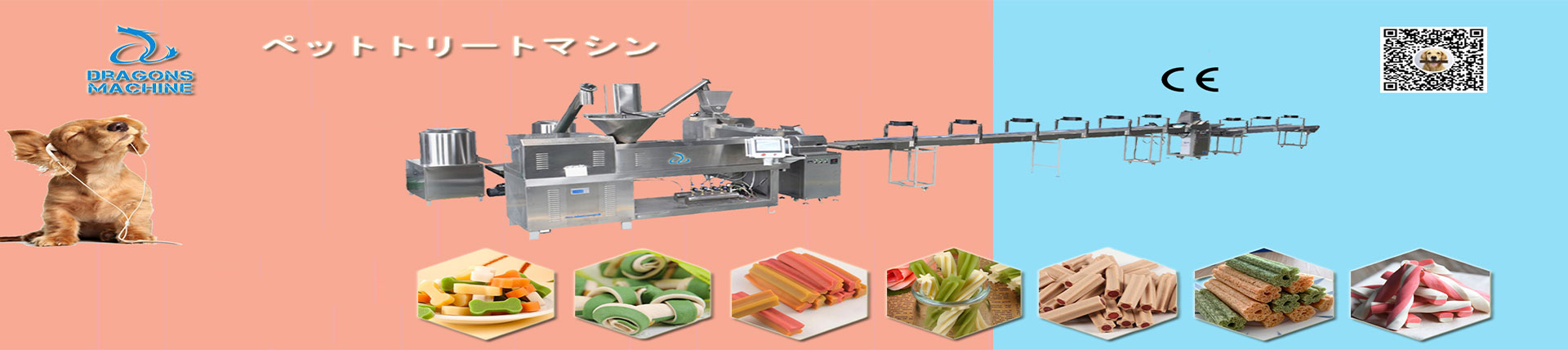

Food Extruder Machine Supplier to explain the knowledge of puffing.

Puffing is a food processing method. Processed food is placed in a closed container. After heating and pressing, the pressure is suddenly decompressed. The water in the food vaporizes and expands, causing many small holes in the dog food to become crisp and become puffed. The basic principle is to let the raw material suddenly decompress and expand under heating and pressure. Puffing technology as a new type of food processing technology started in 1910. In the pet food application, in the 1950s, the earliest use of the extrusion principle in the United States to produce pet food, that is, using the screw and screw sleeve in the extruder to pressurize and pressurize the raw material, and The high-temperature and high-pressure food is extruded into the die hole, and the solid pressure is suddenly reduced to achieve rapid volume expansion.

The puffing process is also a process of shaping the raw material of dog food. During the molding process, the water is added in the form of steam, and the starch of the dog food is gelatinized and heated to 100 ° C - 1800 ° C. Because the pressure before extrusion is large, the pressure is released instantaneously upon extrusion, and the moisture rushes out of the particles, thereby The dog food is rapidly expanded and foamed, and the water evaporates. Therefore, the dog food that has undergone the expansion process generally has a high nutritional value that is easy to digest and absorb.

For more information on Rajgira Ladoo Cutting Machine, please follow our website, http://jp.dragonextruder.com

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語